- Humane handling

- Improve employee morale, less turnover

- Higher yields

- Improved meat quality

- Greater ROI and consumer relations

- Designed and manufactured in the US

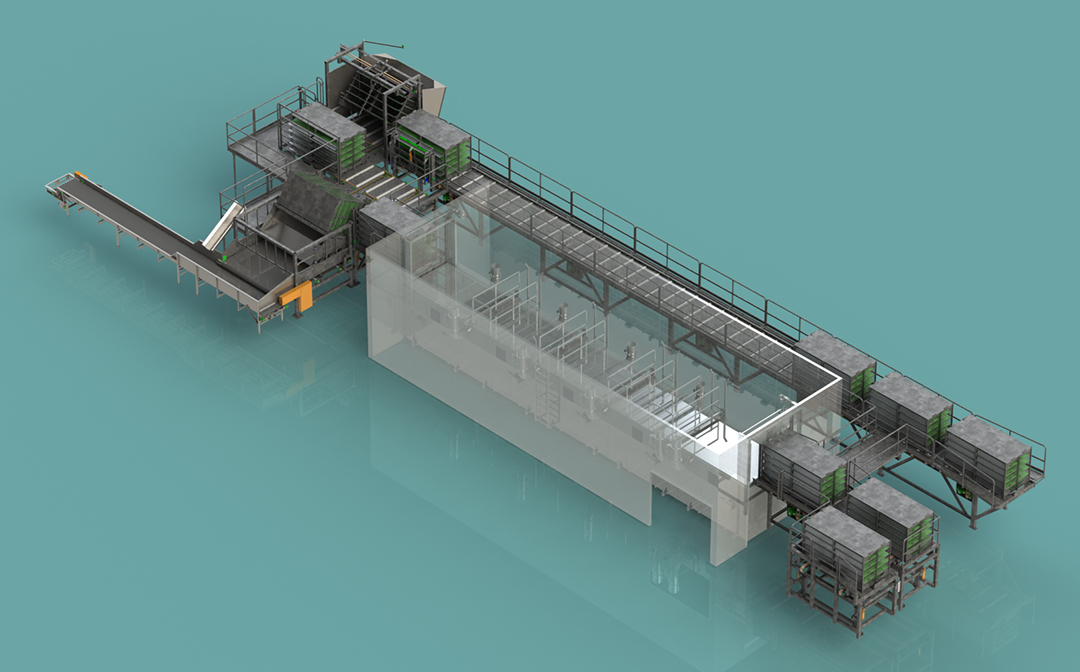

Humane-Aire is a registered treadmark of Midway Machine Technologies. Founded in 1987, Midway Machine Technologies serves the food industry with automation system design and building. A knowledgeable team of engineers and tradesmen provide engineering, fabrication, assembly, installation and parts. Midway has built many food processing systems, including the Humane-Aire CO2 gas-stunning system in use at many poultry producers today.

Since 1951 Bright Coop has been at the forefront of live bird transportation and handling through innovative ideas "brought to life" by its’ experienced team of engineers and craftsmen. In 1979, Bright Coop revolutionized the poultry industry by becoming the first to manufacture and distribute a more modern way of transporting and unloading chickens at the slaughter plant. Most recently, Bright Coop has teamed with Midway Machine Technologies in Zeeland Michigan to manufacture and distribute the fully automated "Bright Coop/ Humane-Aire Controlled Atmosphere Stunning System.

CLEANER WORK AREA

Less fluttering and stressed bird handling translates to minimal dust, feathers, dirt, excrement, noise and debris.

A LEANER SYSTEM

There are fewer variables than traditional electrical stun systems; less disruption and more predictable results.

OFFERS OPTIONS IN CO2 PURCHASING

Humane-Aire does not require OEM carbon dioxide, allowing you to leverage your CO2 purchasing for greater flexibility.

ADOPTION BY LARGE SCALE QSR

Responding to consumer input for humane processing, several large quick serve restaurants have recently announced their preference for suppliers using CAS processing.

REUSE CO2 FOR LOWER COSTS

Greater effectiveness in stunning, through a specially designed tunnel that allows for reuse of CO2.

LESS HANDLING, LESS STRESS

Birds are stunned in the original crates and not handled until after stunning, when they are relaxed from the gas. This eliminates fluttering during shackling as well as damaged carcasses.

HIGHER EMPLOYEE MORALE

Greatly improved working conditions in what is traditionally the least desirable department of the production facility.

HIGHER YIELDS

Fewer downgrades from blood spots and fractures, less trimming and better color.

MARKETING OPPORTUNITIES

Today’s protein buyer — both trade and consumer— is more aware than ever of feed sources, product quality and processing. An educated consumer is more apt to purchase quality product — and less likely to settle for a commodity. The retailer and foodservice operator sells a consistently better protein that displays better.

CONSTANT AND PREDICTABLE BIRD SEQUENCING

Unlike batch-type systems where bird timing is unpredictable, the continuous rate of our inline stunning system maintains consistent timing to ensure easy bleeding and picking of a relaxed bird.